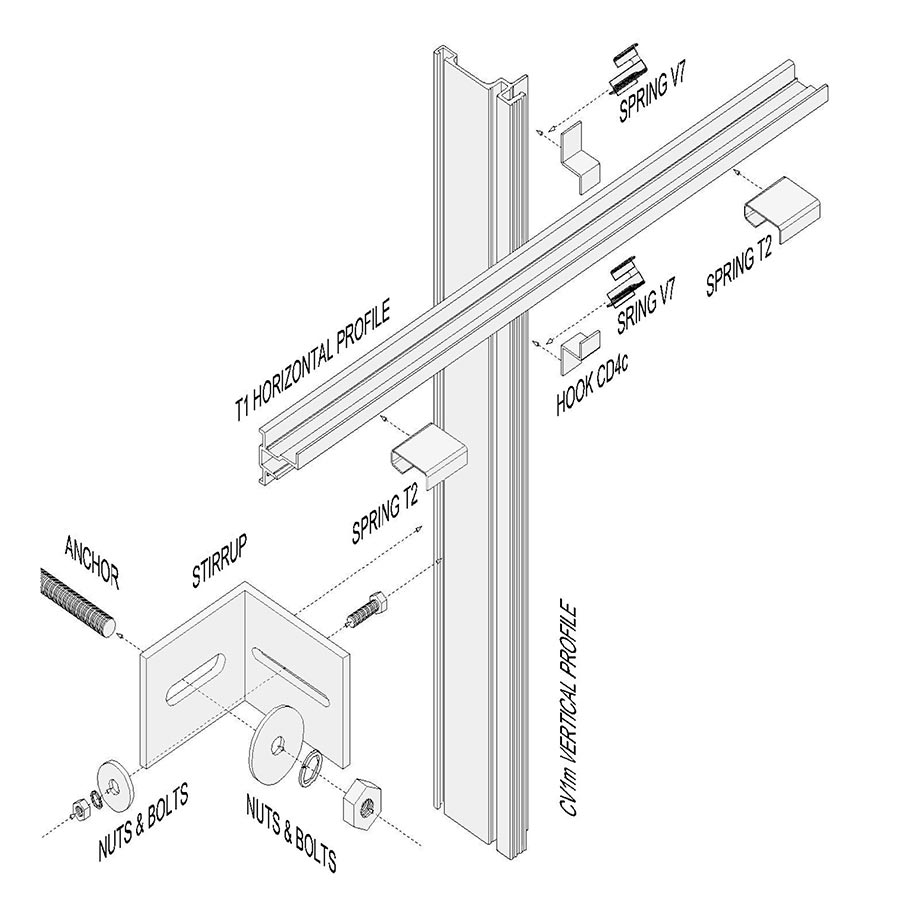

SYSTEM TYPE:

Hidden anchors

WORKINGS ON TILE:

Kerfs on slab edges

CLADDING SLABS TYPOLOGY

– Thick stone slabs, simple or multi-layer

– Thick reinforced-concrete slabs

– Terracotta panels

– Other thick materials on which is possible to make kerfs on the edges

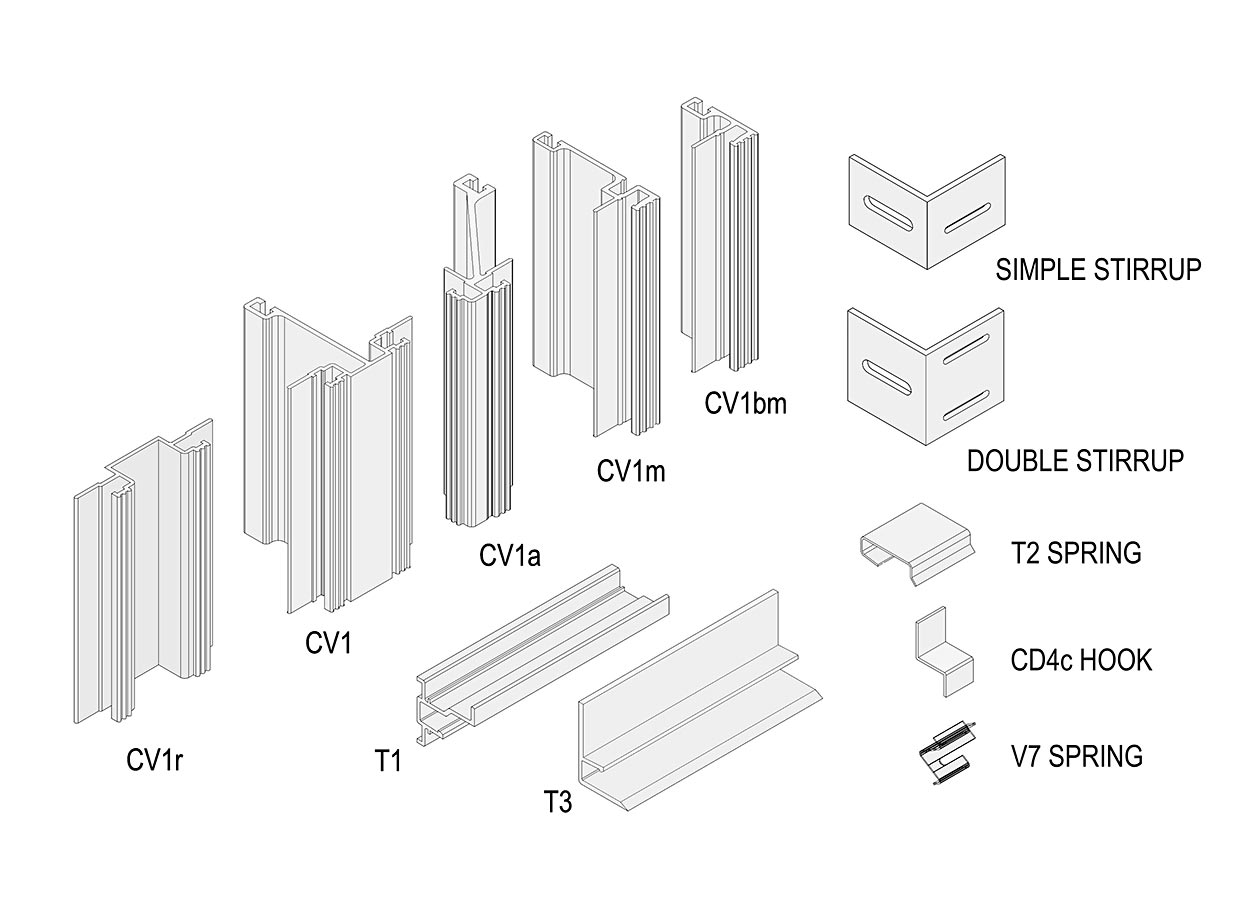

SYSTEM COMPONENTS

The “Terra” system is made of these components:

– extruded profile type “CV1m” in aluminium alloy EN 6060 T5 (or similar, when needed)

– extruded profile type “T1” in aluminium alloy EN 6060 T5 (or similar, when needed)

– hooks type “CD4c” to support the horizontal profile “T1”, in stainless steel EN 1.4310 (AISI 301)

– springs type “V7” to fix hooks on “CV1m” profile, in stainless steel EN 1.4310 (AISI 301)

– standard supporting stirrups type “A12” e “B12”, from extruded profile in aluminium alloy EN 6060

– hooks type “T2” to retain slabs on the horizontal profile “T1”, in stainless steel EN 1.4310 (AISI 301)

– nuts and bolts to fix “CV1m” profile on the stirrups, in stainless steel class A2

– anchors to fix the stirrups on the wall, mechanical or epoxy-resin based, as needed

– neoprene gasket strips, to gauge the slabs, the hooks and the aluminium profile, in different thickness as needed

– springs type “lana” in tempered stainless steel, to support the insulating panels and press them on the wall surface, when thermal insulation is needed

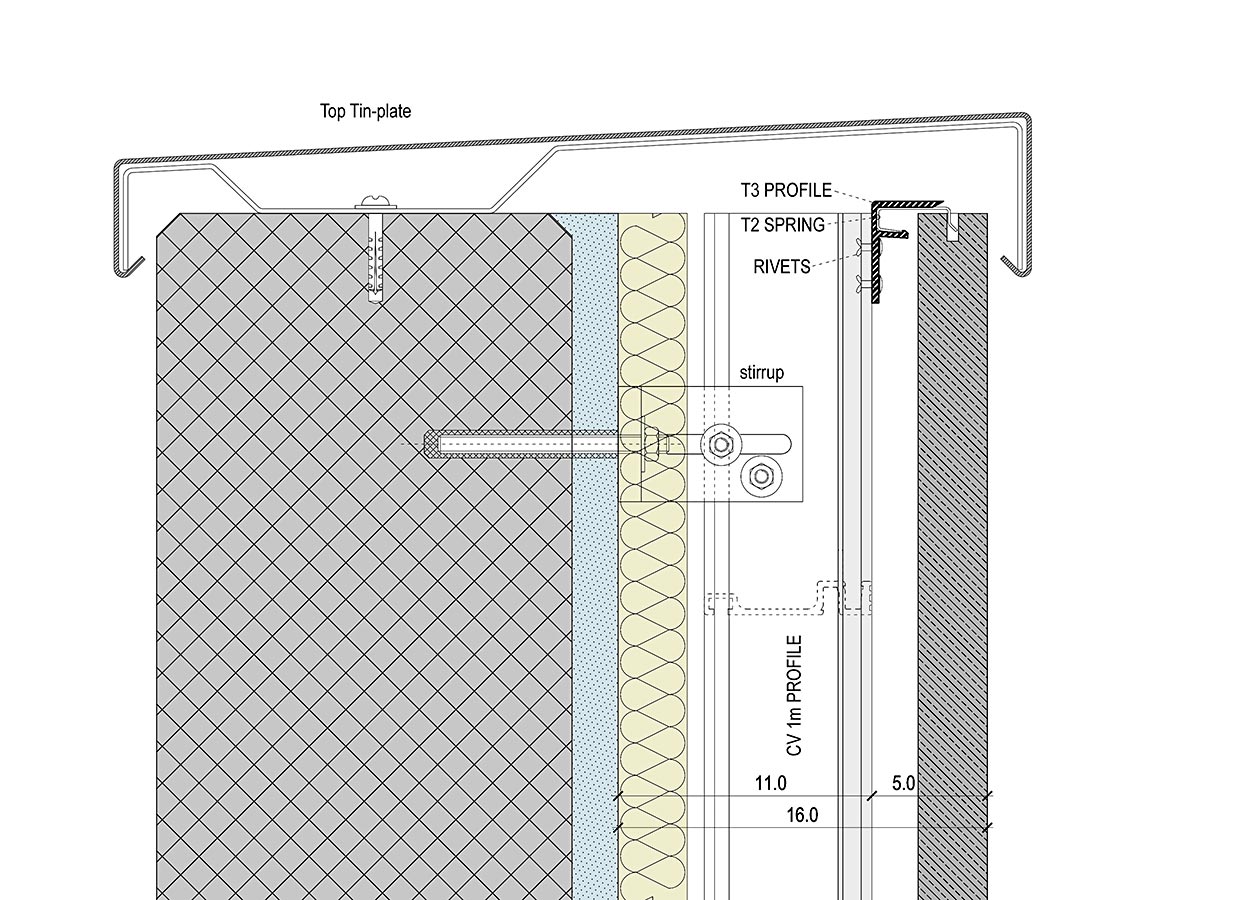

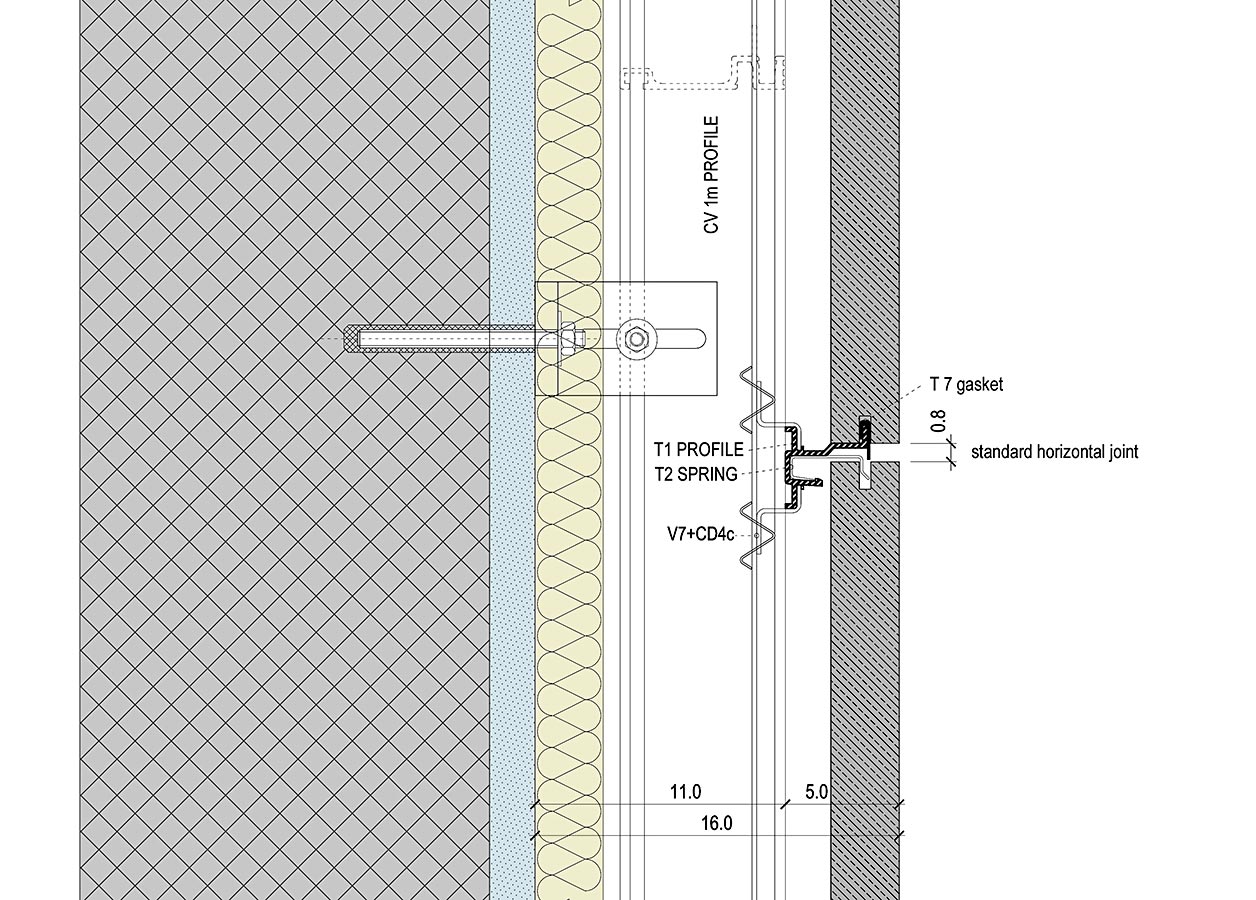

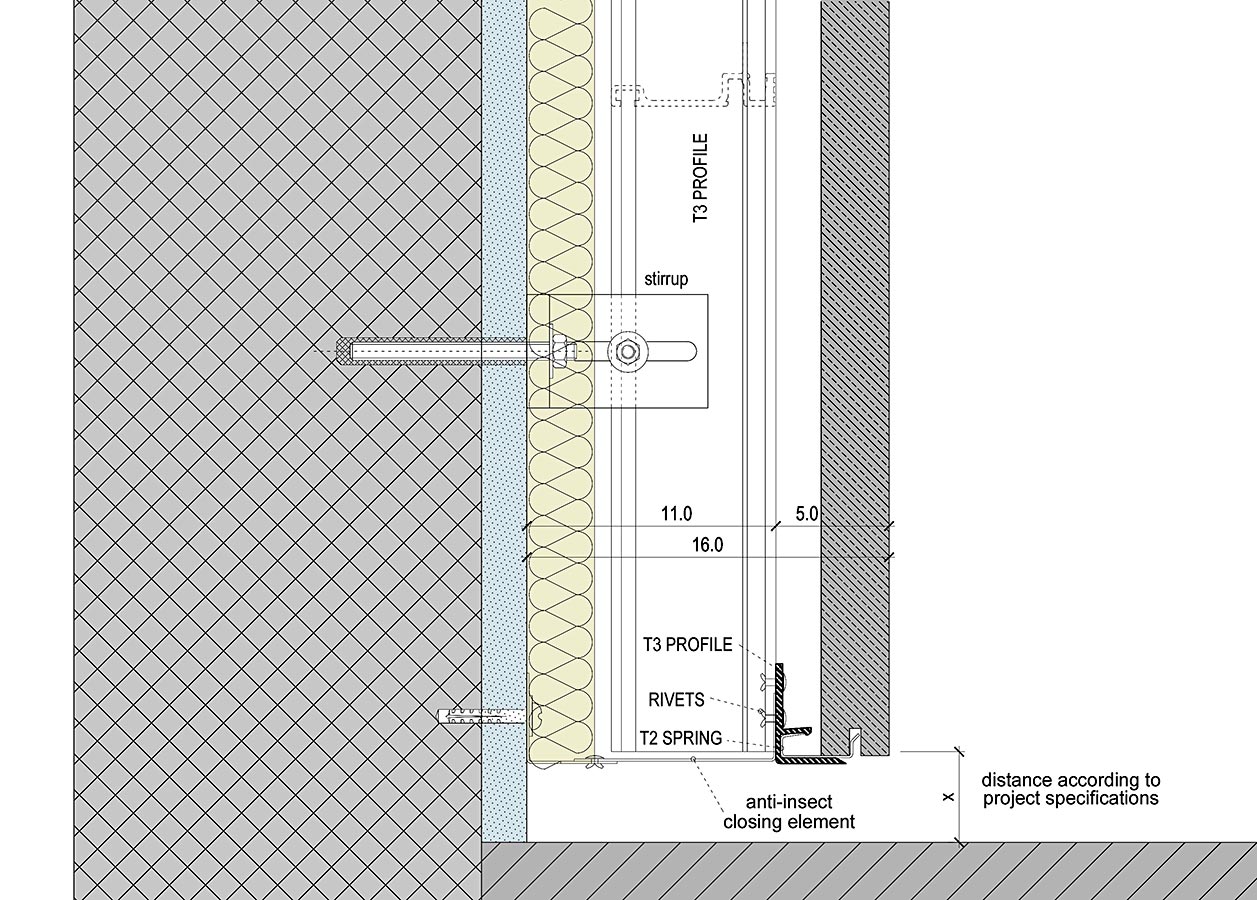

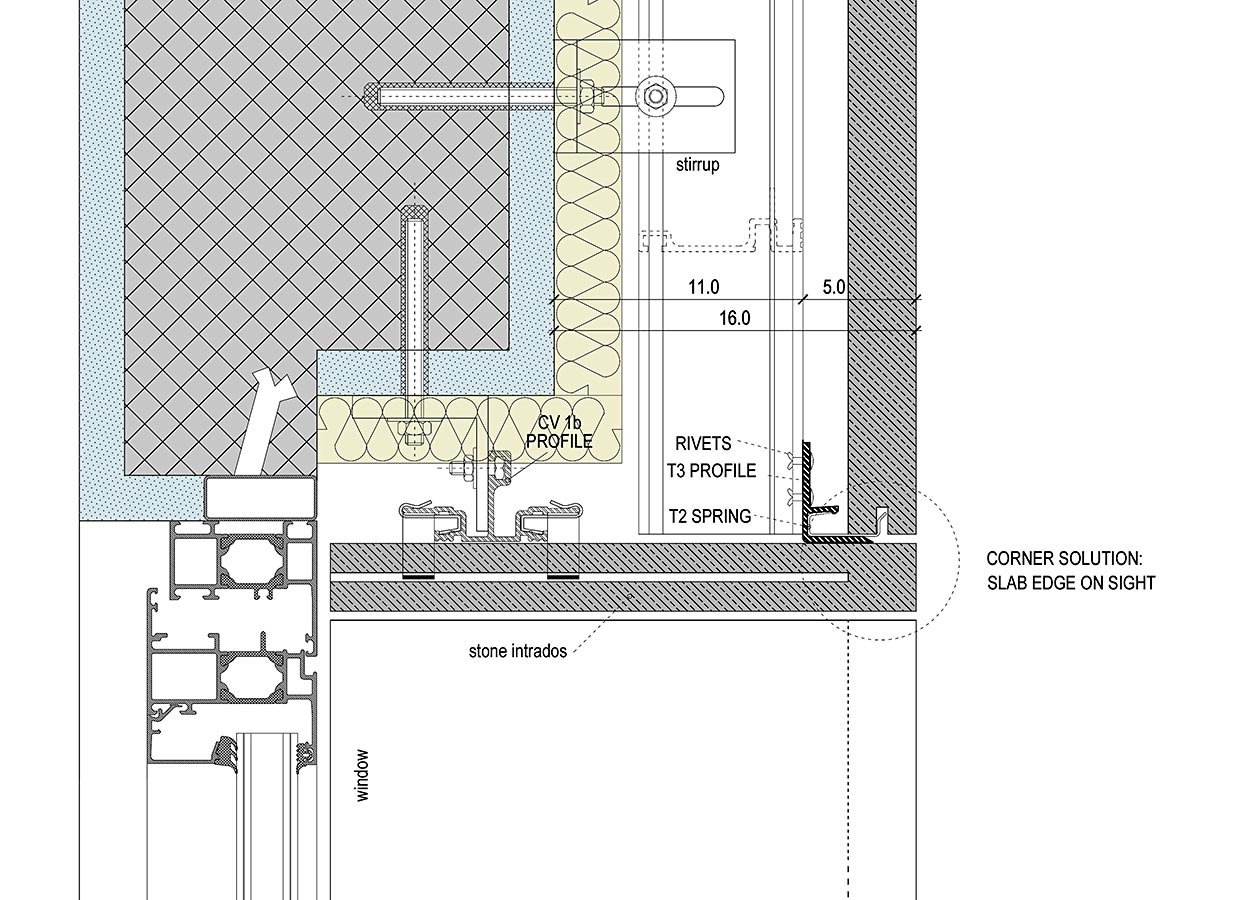

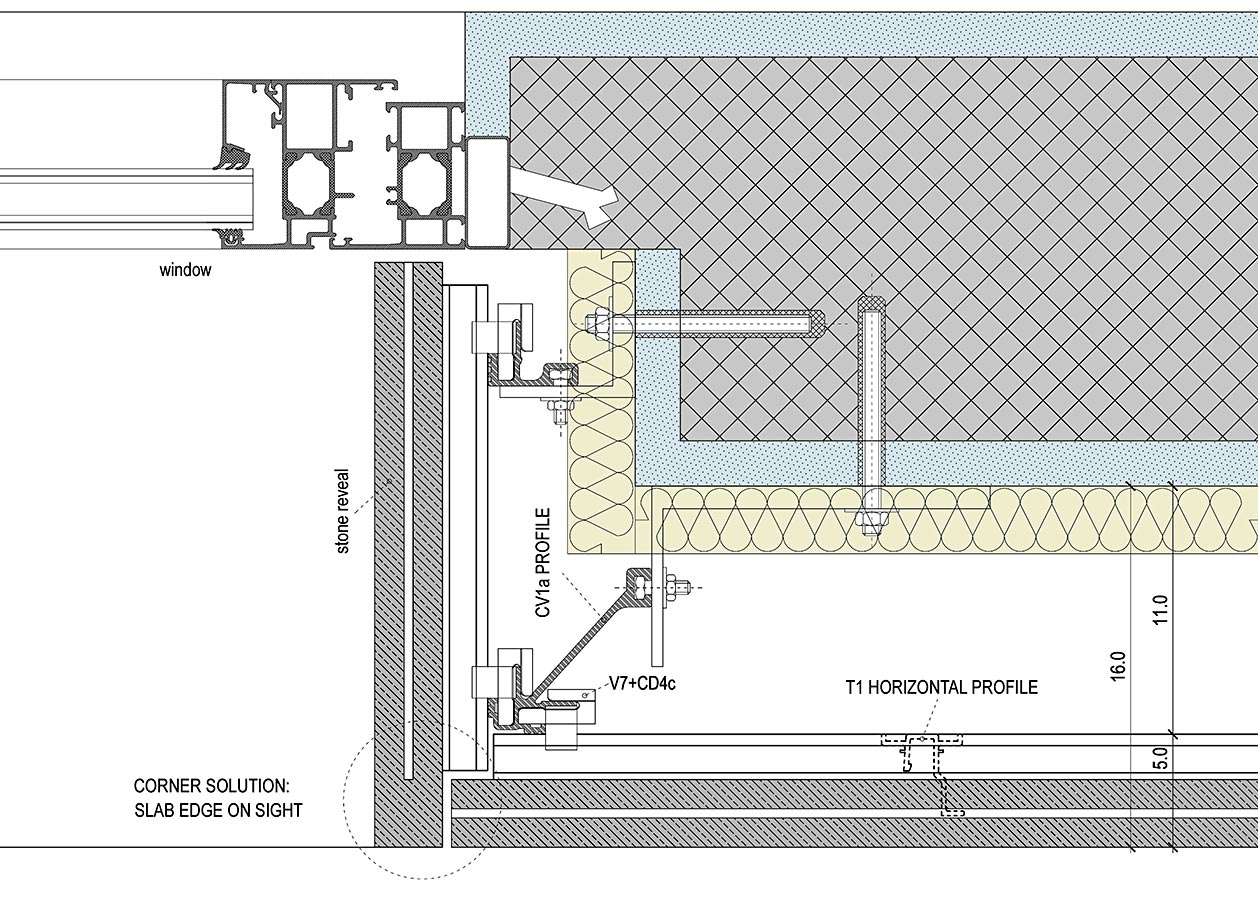

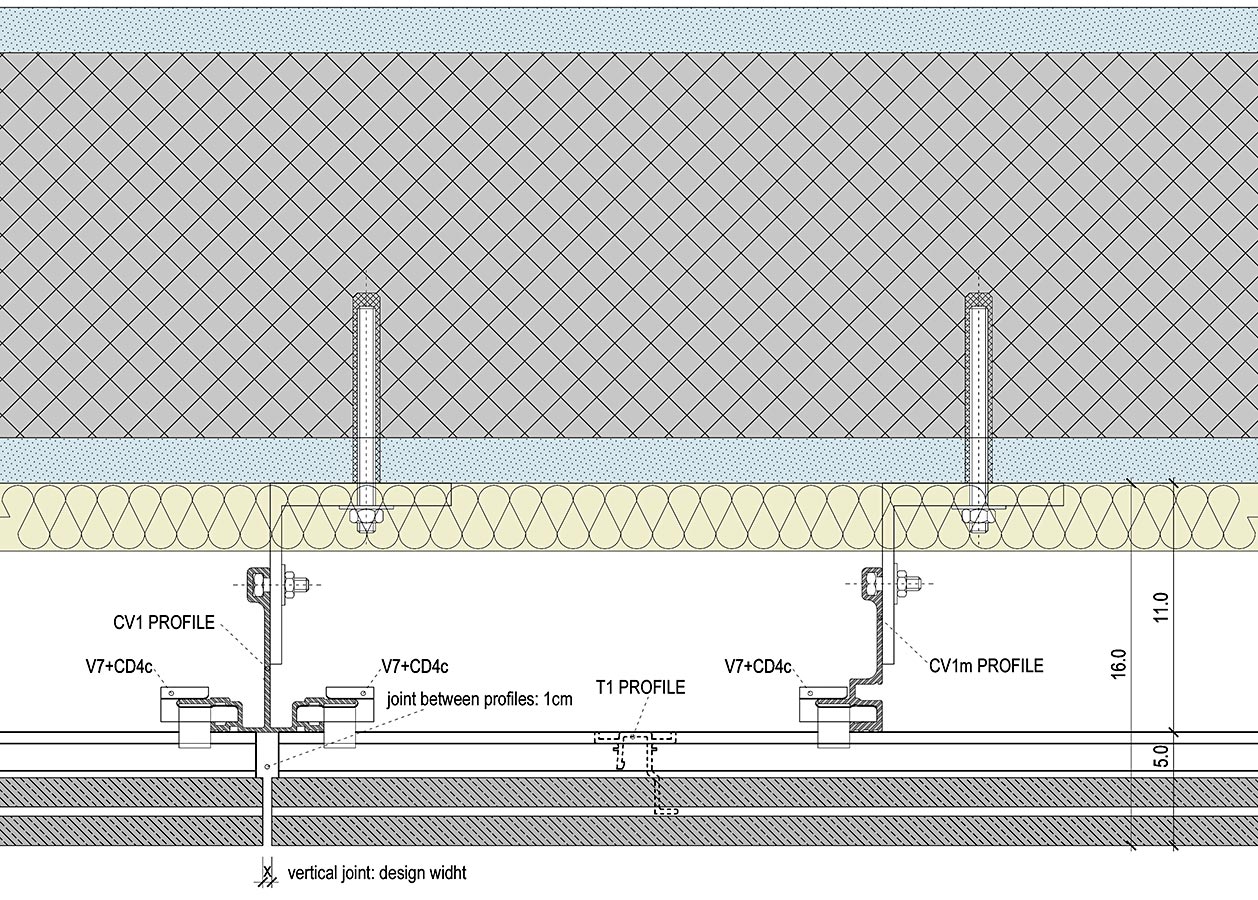

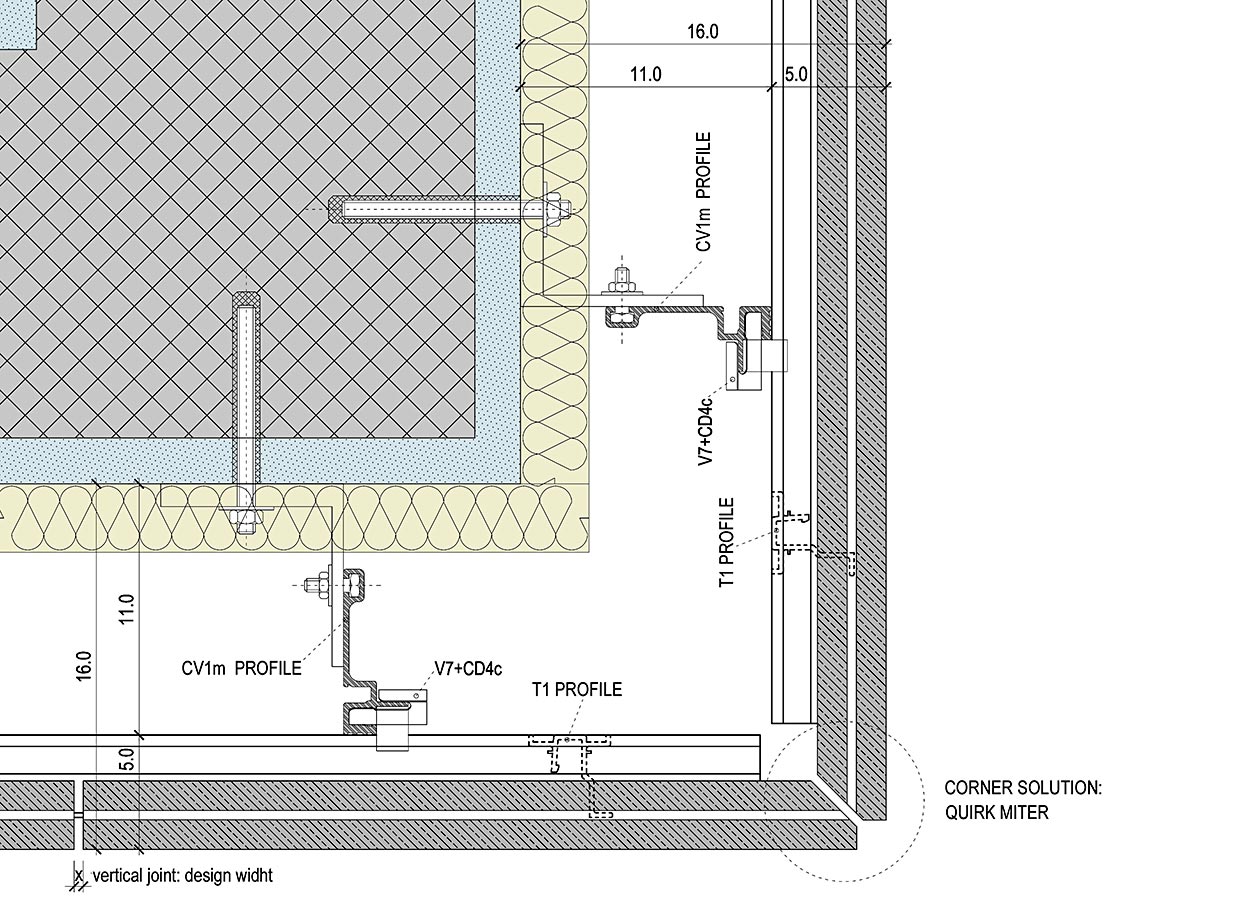

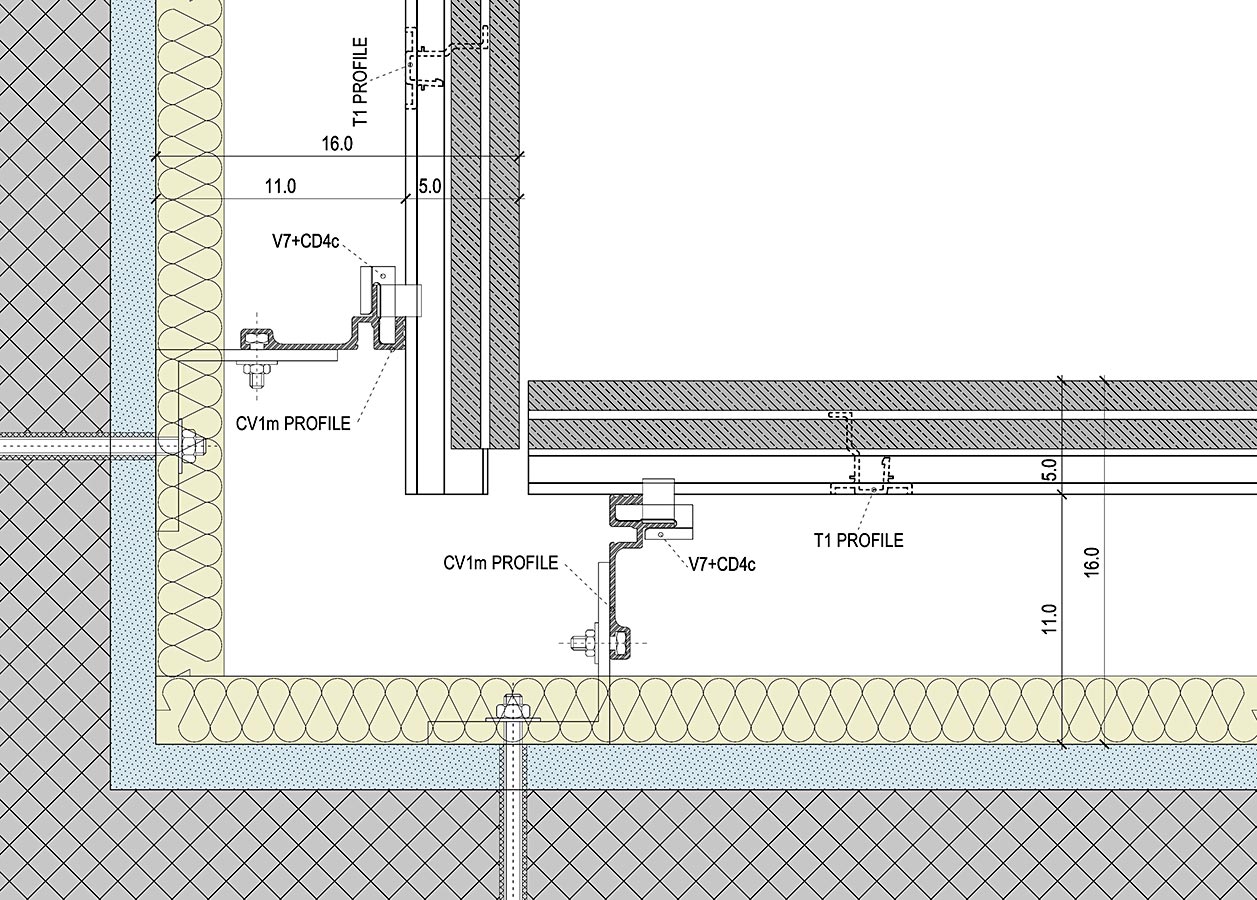

SYSTEM SIZES

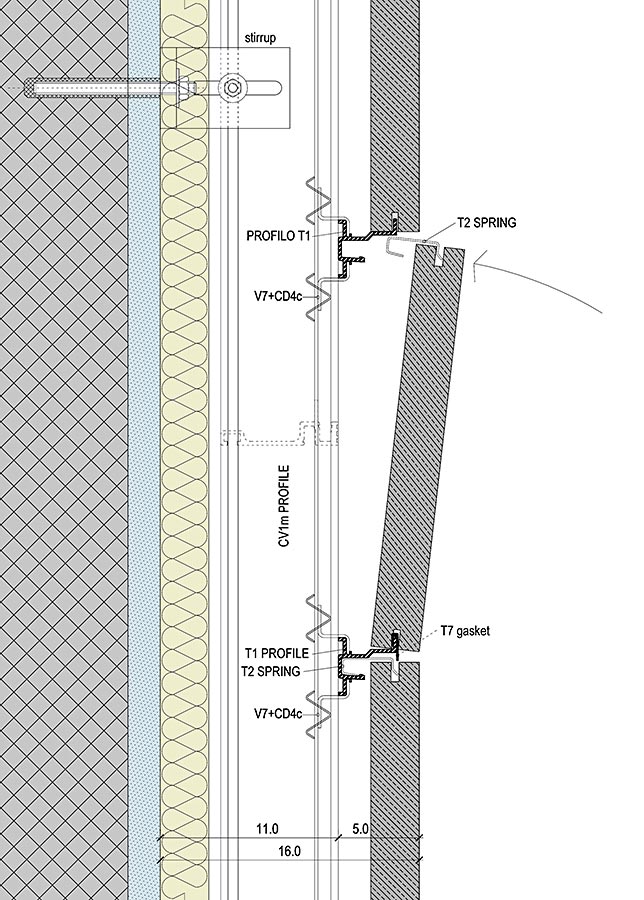

– The standard distance between the wall and the MIDDLE of the slab is 145 mm, with a standard regulation of ± 25 mm. (If the slab is 30 mm thick, this position matches a standard distance between the wall and the external face of the slab of 160 mm ± 25 mm)

– The standard thickness of the slabs for this system is from 20 mm to 40 mm average

– The standard kerf for the slab is 5 mm wide and 12 mm deep.

SYSTEM DESCRIPTION

The vertical mullion “CV1” is put in place on the wall with its design pace, the horizontal profile “T1” is fixed on the vertical profile along the horizontal joint between the slabs, with a pace depending on the slabs heigth and the horizontal joint between them.

The “CV1m” vertical profile is designed and shaped in order to fit without drillings the following components:

– the stirrups supporting the mullions on the wall, put in place with their design pace

– the hooks “CD4c” to support and fix the “T1” profile, and the fixing springs ”V7” , to be inserted using a small hammer in the proper groove of the vertical profile

– the insulation springs, if needed

The “T1” horizontal profile is designed and shaped in order to fit without drillings the following components:

– the cladding slabs, whose inferior kerfs wedge directly in the “T1” profile wing;

– the hooks “T2”, to be inserted in the superior kerfs of the slab and wedge into the “T1” profile;

This arrangement of the components protects the coatings (oxidation or painting) from corrosion and assure the structure a longer lifetime.

This “Terra” system makes possible to set up medium/large stone slabs by a completely invisible system, but requires that each slab have a continuous kerf in the superior and inferior edge, so that the hooks can insert into the kerfs and are not visible from outside the façade. Each slab is supported by the inferior horizontal profile “T1” and retained by the superior hooks “T2”, the number of “T2” hook per slabs depends on the slab dimensions (usually two hooks).

Each slab is solidarized with the hooks and the horizontal profile using neoprene gasket strips of useful thickness and silicon drops, when needed. When all the components are put in place, each slab can be set up or dismantled one at a time.

The supporting structure makes possible any type of regulation and it is able to protect from wind action and to allow the thermal expansion of all the components.